sheet metal drawing operation is used to make

With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces. Sheet is held by jaws or.

Sheet Metal Forming Processes And Equipment Machinemfg

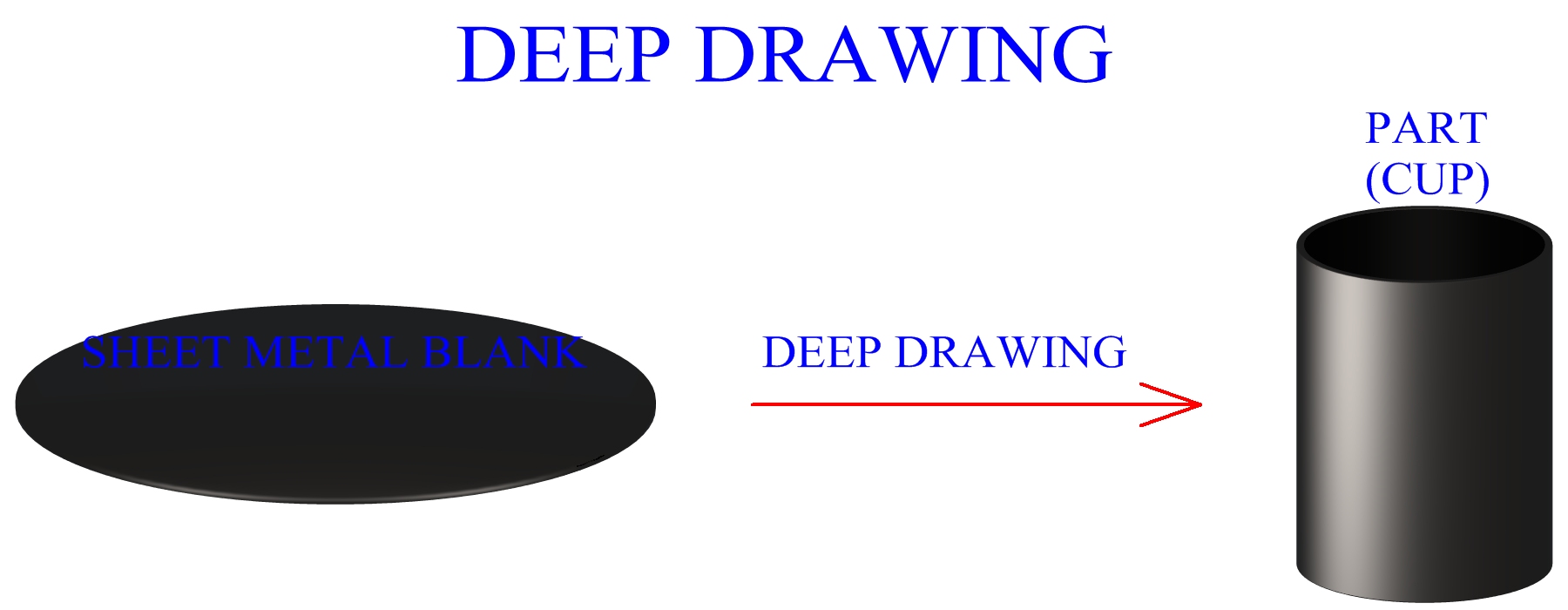

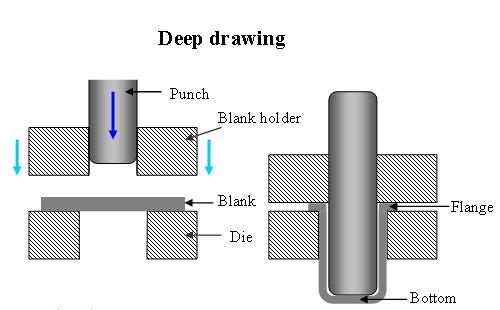

For deep drawing the sheet is drawn radially over the surface of the die by a punch.

. Sheet metal is one of the very convenient ways that is used in metal. Deep drawing operation in sheetmetal is a widely used sheet metal forming Operations in the automotive and consumer goods sector to manufacture sheet metal parts. In a sheet-metal-cutting operation used to produce a flat part with a hole in the center the part itself is called a blank and the scrap piece that was cut out to make the hole is called a slug.

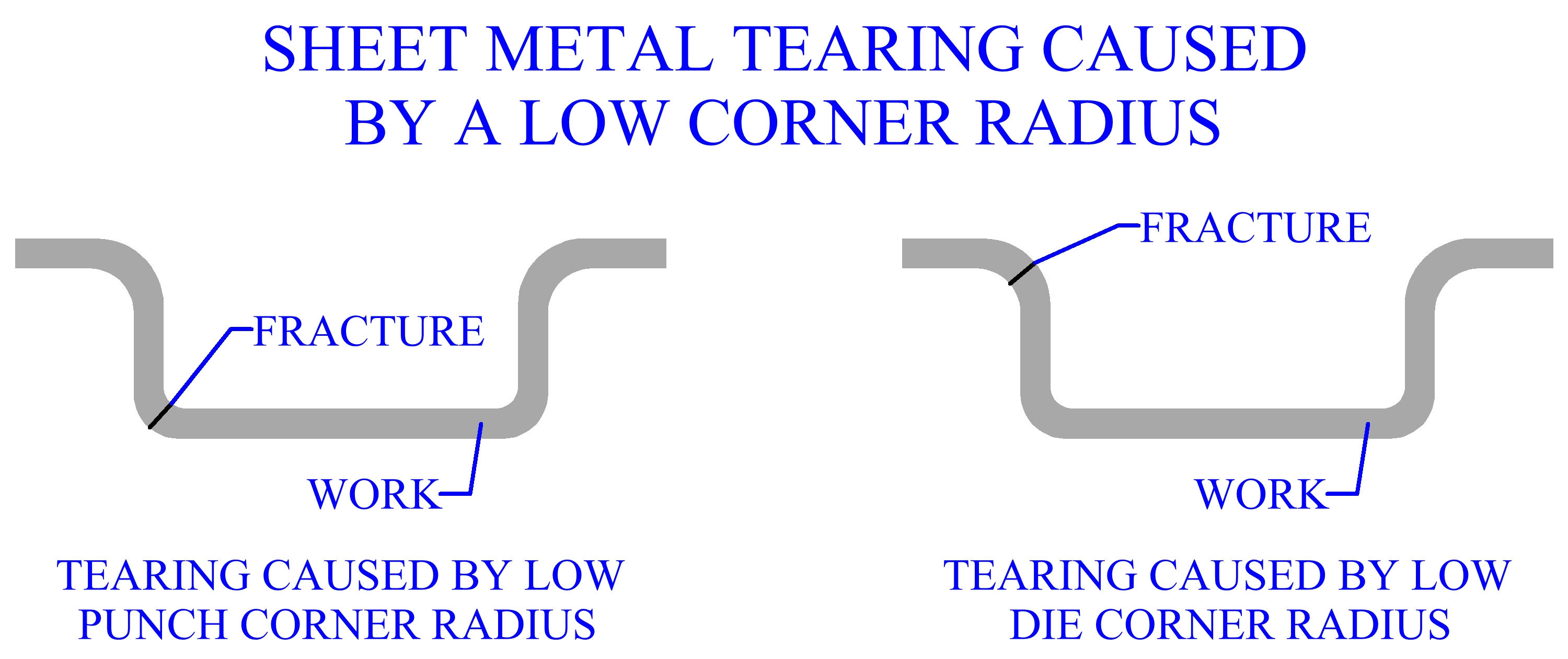

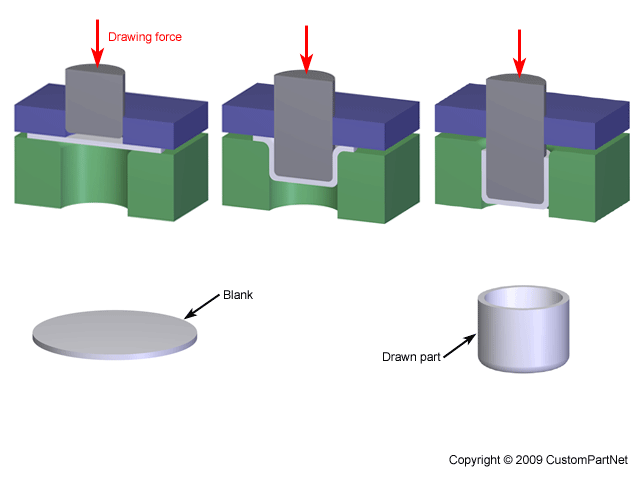

Sheet metal operations are mostly termed cold metal operations without heat or fire like shearing and cutting with the use of guillotine and saw punching to form metal parts. Drawing Sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts Performed by placing a piece of sheet metal over a die. As the metal is drawn it stretches to become thinner to achieve a desired shape and thickness.

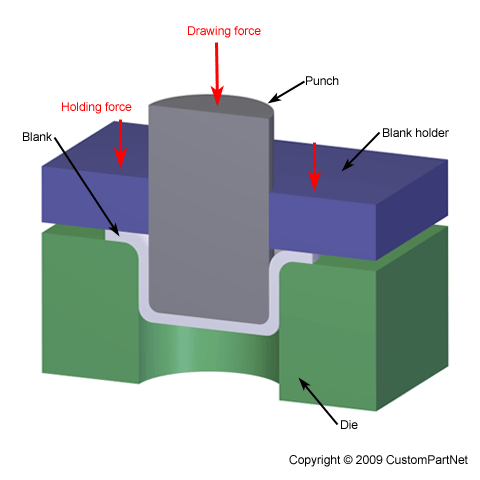

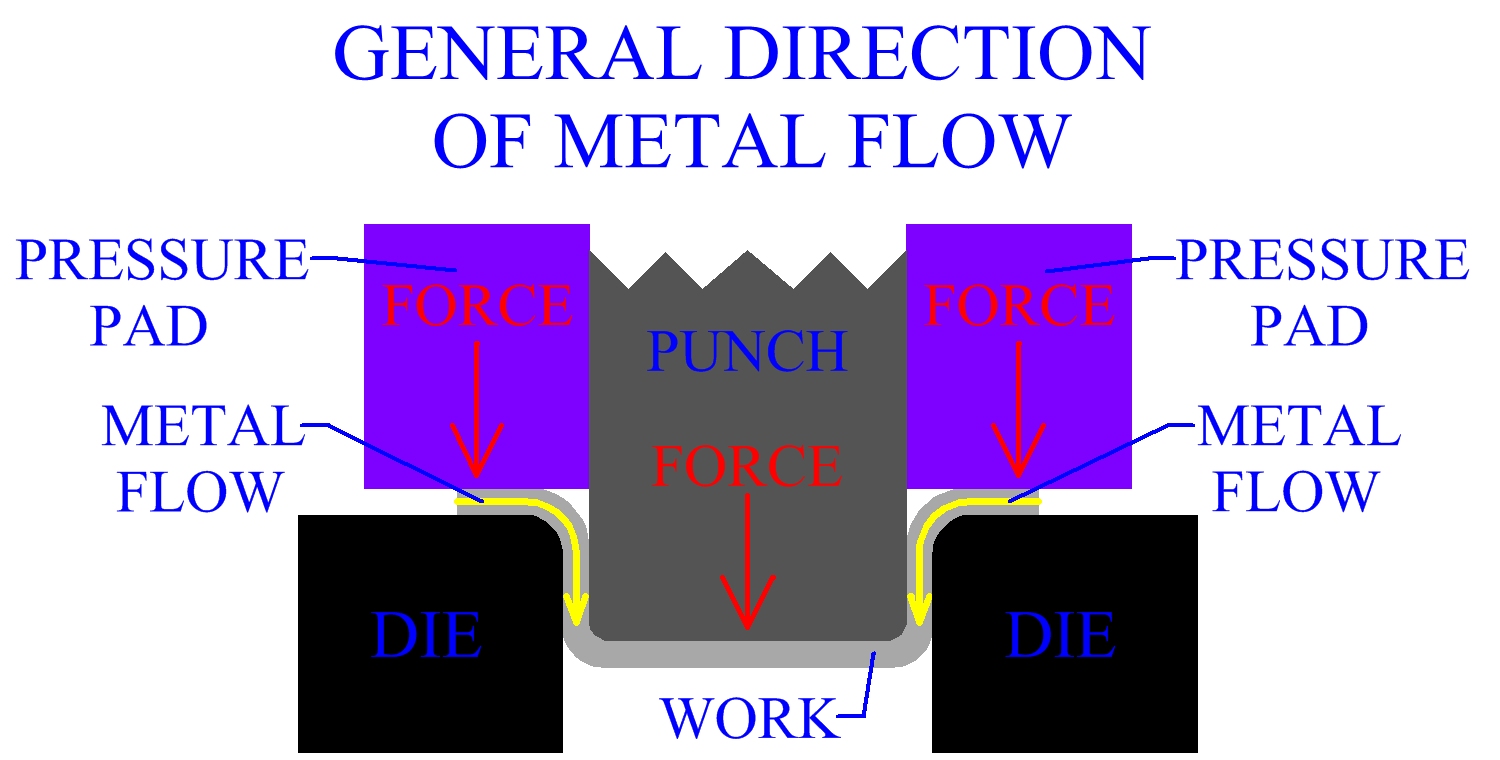

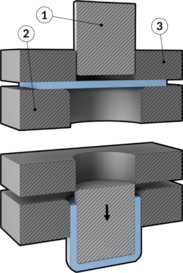

1 The blank of sheet metal is placed onto surface of die. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts. 3 The punch moves downward into the die operation to complete drawing operation.

In Deep drawing operation when the force is applied by using the punch the sheet is simply pulled into the die without any shearing action and taking the shape and size same as that of. Sheet metal drawing operation is used to make a wire. The punch-die clearance is slightly larger than the thickness of the sheet metal to be deep drawn.

Sheet metal Drawing Operation involves drawing sheet metal parts in a cup-like shape by utilizing a bending press. Under pressure the rubber and sheet metal are. True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the.

Drawing is a metalworking process that uses tensile forces to stretch metal glass or plastic. The punch is the desired shape of the base of the part once drawn. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts.

This process is very extensively used in the automobile industry to achieve a. Rubber pad forming RPF is a metalworking proc ess where sheet metal is pressed between a die and a rubber block made of polyurethane. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and.

The process involves a punch with a round comer and a die with a large radius. The die cavity matches the punch and is a little wider to. Compared to hot drawing cold drawing offers greater.

The sheet is supported over die surface by a pressure ring which bears on the upper surface of the sheet. FIGURE 30 The metal-forming processes involved in manufacturing a two-piece aluminum beverage can. A Schematic illustration of the deep-drawing process on a circular.

Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change. 2 The blank holders hold the blank onto the die. Drawing is a metalworking process which uses tensile forces to stretch metal or glass.

Answer 1 of 4. Drawing is accomplished by placing a piece of sheet metal. Deep drawing of sheet metal is performed with a punch and die.

Known as cold drawing its a highly effective metalworking process for manipulating the shape of metal. As the metal is drawn pulled it stretches thinner into a desired s.

Sheet Metal Forming An Overview Sciencedirect Topics

Sheet Metal Forming Processes Total Materia Article

Pressing Deep Drawing Process Roy Mech

Sheet Metal Forming Basics Processes And Material Used

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing Find Suppliers Processes Material

Deep Drawing Metallurgy For Dummies

Drawing Process An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

9 Different Types Of Sheet Metal Operations With Diagram Pdf